"I wanted to express my gratitude for our phone conversation today. I am pleased to be engaging with Tilgear for my professional needs. As a DT Technician in the Technology Department at Millais School, my role here involves ensuring our department is well-equipped and functioning smoothly, which naturally leads me to rely on quality suppliers and efficient service. As a customer, I am looking forward to your support and assistance in the future. Your expertise at Tilgear is something I value greatly, especially when it comes to selecting the right tools and equipment for our school's needs. I am confident that your guidance and service will be immensely beneficial." - DT Technician, Millais School "Thank you for the excellent service your company provides for this school. Your staff are always kind very helpful you always deliver your products on time. Keep up the high standards." - Trinity Catholic High School, London "You have been very thorough and helpful Neil. An amazing experience so far 10/10 for service I must admit" - D Shah, Designed with Elegance UK "I have used Tilgear to supply us with goods since 2014 when I started as a Construction Technician. Having since moved on to two additional colleges I’ve always made sure we did business with Tilgear. The team always extremely helpful and professional and will always go the extra mile to supply our goods, even if it’s not a stock item. Any issues we have they will sort them for us. I recommend them to any school or College who need a reliable supplier to work with". - Buckinghamshire College Group, High Wycombe. "Over the past two and a half years I have been using Tilgear for purchasing the tool kits for the Lee Marley Brickwork apprentices. I have a good report with the account manager who promptly returns quotes and is always on hand to answer any questions. Once the order is placed, Tilgear quickly turn around the order and get the tools delivered very promptly. I’m very happy with the service I receive from Tilgear!" - Lee Marley Brickwork Ltd, Reading "All received today and a very happy year 6! They couldn't build cars last year as our usual supplier was out of stock of the parts for some 6 months so we're really happy we can get all the bits from you now instead!!" - Federation of Winklebury Infant and Junior Schools, Basingstoke "I just want to thanks you for delivering the workbenches last week and your engineer who worked very hard to have them all ready for us on time. Excellent job and excellent service!" - Flexit FF&E Solutions, Leeds "They arrived yesterday morning, super quick. Thank you so much they were exactly what we needed." - Benjamin Britten High School, Suffolk "WOW – what service. Thank you so much." - North Berwick High School, East Lothian "All received and mechanical department are happy with the bits. Thank you for your assistance with this and will keep you in mind for future purchases." - Bedford College "Fantastic customer service!" - The Purbeck School, Dorset "Thanks for touching base, we are extremely happy at our end pricing is excellent compared with other suppliers. Many thanks! "- The Three Rivers Learning Trust, Northumberland "We have had fantastic support so far and really competitive prices." - Sacred Heart High School, Newcastle upon Tyne "We received our order in speedy time as always and never had an issue. We do only ever order small amount of items, but if we do require anything in bulk I will be sure to contact yourself." - Scotland’s Rural College "You were really speedy and we will defo use you again." - Haileybury Turnford, Hertfordshire "Thank you very much for your and the rest of your crew for their assistance in getting this sorted so promptly. It really is appreciated by all our dept staff." - Wolverhampton Girls High School

WHY CHOOSE TILGEAR

Tilgear - tools for the education sector for the last 50 years with all the resources required for the design technology departments.

- Over the years, as the curiculum has evolved, so has our

- range, offering the latest Tools, Machinery, Consumables and Materials to the Design Technology departments.

- College Vocational courses are also fully catered for with vast ranges of Construction Tools, Automotive Equipment, Painting & Decorating Supplies and Electrical Tools.

- The new UTCs and Engineering Colleges find a vast range of Engineering equipment stocked in our warehouse as well as Lathes, Mills and CNC Machines. Laser Cutters and 3D Printers continue to be some of our most popular products.

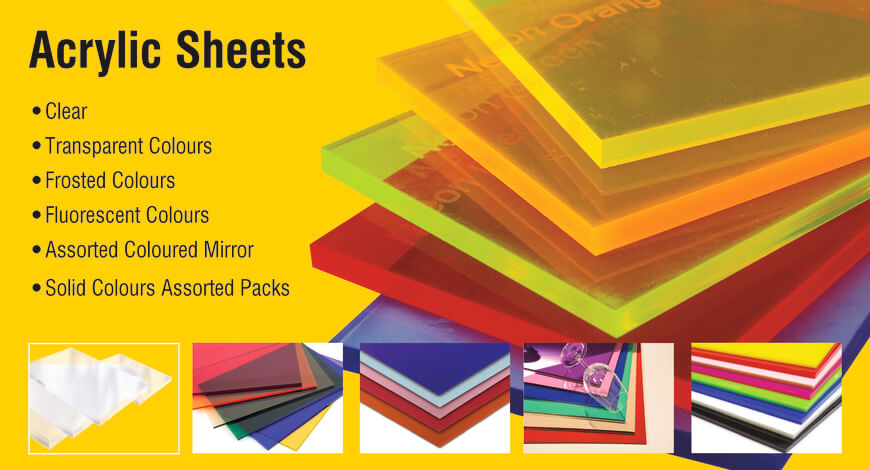

A vast range of materials awaits - Acrylic Sheets, Acrylic Rod, HIPS Sheets, Laserable Ply and Smart Materials.

From full workshop installations, storage solutions, benching, machinery, materials and day to day design technology supplies, Tilgear has it all.

We deliver 'turn key packages for new workshops, legacy equipment audits and will also source that obscure product that you can't find anywhere.

Tilgear is your one stop shop for every element required in the DT workshop.

All prices are plus VAT. Our contact e-mail address is sales@tilgear.co.uk

Latest News

15

February

Tilgear Supports F1 in Schools Challenge

In December, Tilgear was proud to support the F1 in Schools STEM Challenge launch event in Shropshire. Spanning age ranges of 9 to 19, F1 in schools aims to help change the perceptions of science, technology, engineering and maths. By creating a fun and exciting learning environment for young people, it helps learners to develop an informed view about careers in engineering, Formula 1, science, marketing and technology....

10

January

Stocking Up for Exam Time with New Offers from Tilgear

2020 has arrived. We know that for many of you, the new year term is when attention turns to exam time and stocking up on materials for exam projects. From new sketch books to paints, acrylics and woodwork supplies, our new Essentials Catalogues are here to help and are bursting full of great value deals.

...12

December

Thank You from All of Us at Tilgear

From all of us at Tilgear, we would like to thank you for your business this year and wish you and your families a great break and prosperous 2020. 2019 has been a busy and exciting one here at Tilgear and we're looking forward to carrying on that trend in 2020!...

07

November

Introducing Mayku Teach: Online Resource for Teachers

Mayku, creators of the world’s first desktop vacuum former - The FormBox - are launching an accompanying online teaching platform to bring joy into learning STEAM subjects....

15

October

Turning Ideas into Inventions with littleBits

Looking for ways to make STEAM learning more fun, interactive and engaging for students? littleBits are open-source, electronic building blocks that put invention at the heart of learning through play....